Cleaning - 5.1 Cleaning and sanitizing

Cleaning and sanitizing are important steps in all production systems. If done improperly, they can contaminate food.

This good agricultural practice applies to all farms.

What needs to be done

Properly clean and sanitize facilities, equipment, vehicles, washrooms and food contact surfaces where necessary to protect food from contamination.

How to do it

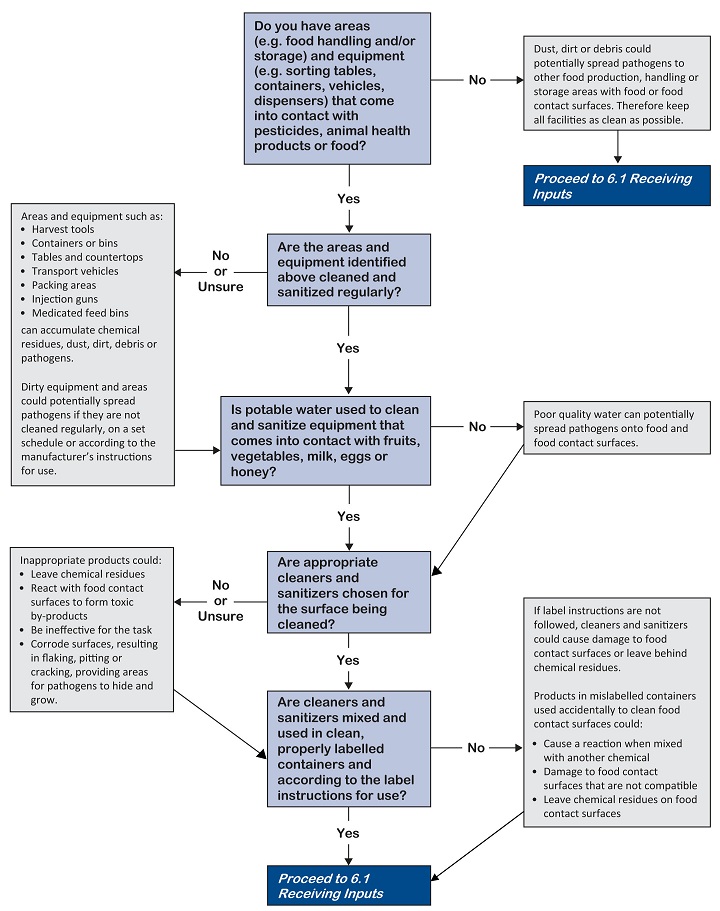

Identify what needs to be cleaned and sanitized.

Areas (for example, food handling and storage) and/or equipment (for example, sorting tables, containers, vehicles, dispensers, fans) that come into contact with or are associated with the use of pesticides, animal health products or food require some level of cleaning and sanitizing.

Cleaning can vary according to the desired outcome (for example, simple surface sweeping; rinsing with clean water; power washing with hot water and soap followed by disinfecting, followed by a final clean water rinse; or using a flushing sequence in feed mixers to remove residues from previous mixes).

Develop written practices. Generally written practices are developed when:

- concentrated chemicals are mixed and used.

- detailed instructions must be given to remove residues from equipment or surfaces.

- pre-determined frequencies for cleaning and sanitizing must be followed.

- there are unique cleaning situations (for example, flushing mixers of livestock medicated feeds).

A practice should:

- Identify who is responsible for cleaning which area or piece of equipment.

- Specify the frequency of cleaning (for example, daily, weekly or after use only).

- Describe the appropriate tools required to do the job (for example, gloves, buckets, brushes).

- Specify which product is used for a particular task, and what the contact time should be. If applicable, specify the water temperature requirements and rinsing steps.

- Describe how to clean and sanitize. Include instructions on how to disassemble and reassemble equipment if necessary.

Choose the right cleaning and sanitizing products. Make sure each product is approved for the intended use and mixed at the correct concentration. Ask your suppliers for appropriate cleaning and sanitizing products, or see the reference listing of accepted construction materials, packaging materials and non-food chemical products (Canadian Food Inspection Agency)

Make sure products are safe for use on the surface being cleaned. The best source for product use information is the manufacturer’s label, but in general:

| Surface Material | Precautions |

| Stainless Steel | Use mild, non-abrasive cleaners. The corrosive properties of stainless steel vary with grade; it will corrode when exposed to strong alkalis, acids or chlorine. |

| Galvanized Metal | Galvanized steel will corrode when exposed to alkaline or acidic detergents. |

| Nickel alloys | Any alkali may be used. |

| Plastics | There are many different types of plastic. In general, plastic is more corrosion-resistant than stainless steel but will deteriorate when exposed to organic solvents. When in doubt, obtain advice from the manufacturer. |

| Rubber | Strong alkalis may be used. Rubber surfaces may be damaged when exposed to acidic detergents or detergents containing organic solvents. |

| Tin, copper | Some alkalis can cause corrosion. Slightly alkaline detergents containing silicates are recommended to minimize corrosive effect. Exposure to chlorine will cause some corrosion. |

| Aluminium | Some alkalis and acids attack aluminium. If alkalis are used, they should be of low alkalinity and incorporate silicates. Do not use chlorine. |

| Wood | Wood is very porous and difficult to clean. Clean with detergents and rinse thoroughly. Avoid strong acids and alkalis. |

| Iron drains | Use moderately alkaline cleaners, as acidic ones are corrosive. |

| Painted surfaces | Strong alkaline detergents will deteriorate painted surfaces. |

| Concrete | Rough porous surfaces should be given a smooth impervious coating approved by CFIA to make them cleanable. Use alkaline cleaner, as acid cleaners will corrode concrete floors. |

Adapted from the Food and Agriculture Organization of the United Nations

Use cleaning and sanitizing products properly.

- Mix cleaning and/or sanitizing products according to directions on the product label.

- Follow label instructions for use. These may include thorough rinsing with potable water to remove residues.

- Properly label containers for handling, mixing and storing cleaning and sanitizing products. Clean or rinse containers properly when finished.

In general

- Train workers to follow proper cleaning and sanitizing practices and identify possible food safety hazards.

- Change cleaning and sanitizing solutions (for example, in boot wash stations) when necessary. Organic matter in the solution can reduce their effectiveness.

- When determining chemical concentrations, take into consideration conditions such as pH, hardness, or the presence of buffers in your water source. These conditions can affect the amount of chemical required to effectively clean and/or sanitize.

- Evaluate cleaning and sanitizing practices on an on-going basis for effectiveness and adjust if necessary.

Terms used

Cleaning: The removal of dirt, dust, manure and chemical residues from surfaces. This can be as simple as removing manure from a pen, or a two-step process beginning by removing dirt with soap and water by various methods (e.g. power washer, scrub brush) and then rinsing with water.

Sanitising: A process whereby a clean surface is coated with an approved chemical solution/water mix to kill or reduce pathogens.

Records to keep

- cleaning and sanitizing practices

- use the Form #5: Cleaning and Sanitizing Record or your own record that includes:

- Dates

- What was cleaned and/or sanitized

- Products used and their preparation

- Initials of worker.

If you have an audit

Be prepared for the auditor to:

- Review written cleaning and sanitizing practices and records or verification that only approved products are used

- Observe your facilities for general cleanliness

- Observe workers carrying out cleaning and sanitizing procedures

Laws and regulations

There are few laws that impact on food safety requiring cleaning and sanitation in agricultural production. Generally, these requirements are laid out in laws regarding the processing of meat, fish and other food products, which are outside the scope of this document. Laws which require sanitizing (e.g. for used containers) related to disease management for plants or bees that are unrelated to food safety are also outside the scope of this page.

Milk Industry Standards Regulation, Reg. 464/81, s. 10 (1) under the Milk Industry Act requires that cattle shall be clean and the udders shall be washed and dried immediately before milking. Milking equipment or utensils must be thoroughly cleaned, sanitized and, when not in use, stored free from contamination by dust or other (s. 35 (2)).

Agricultural Produce Grading Act, R.S.B.C. 1996, c. 11, s. 14 (2) (i) provides that the Lieutenant Governor in Council may make regulations respecting the sanitation of places where a farm product is kept.

Canada Agricultural Products Act, Fresh Fruit and Vegetable Regulations (C.R.C., c. 285) Part I.1 s. 3.1 (4) (d) states the produce is handled with equipment that is cleaned regularly.

Calculating PPM solutions

Here is an example for calculating parts per million (ppm) solutions from a concentrated liquid for a large volume of water:

How much concentrated chlorine solutions needs to be added if you require a 155 ppm chlorine solution in one thousand litres of water (264 US gallons)? The bottle label indicates it is a 12 percent sodium hypochlorite solution.

|

Calculation: A (ppm solution needed x B (amount of water in litres) = C (amount of chemical in litres) A = 125 ppm B = 1,000 litres D = 12% x 10,000 The calculation would be … 125 x 1,000 = amount of chemical needed in litres Answer: 1.04 L of 12% chlorine solution added to 1,000 litres of water will create a 125 ppm solution. |