Residual Fibre Utilization Policy

Fibre Recovery Process

The Fibre Recovery Process focuses on improving the use of lower-quality timber in areas of the Ministry of Forests where there is a demand for the residual fibre from secondary users (pulp mills, pellet plants, bioenergy facilities, and other users of low quality logs) and business-to-business relationships have not been established.

The most efficient method of harvesting residual fibre is through business to business relationships between primary harvesters and secondary users. This leads to cost-effective removal of residual fibre through integrated methods. Primary harvesters and secondary users are encouraged to share information on harvesting opportunities and negotiate fibre supply agreements.

Where business-to-business relationships cannot be established, the natural resource district manager may:

- Establish a “Residual Fibre Area” where as ordered, primary harvesters are required to provide notice declaring:

- If they will be using the residual fibre, and

- Whether or not they are abandoning their rights to the residual fibre

- Issue a “do not damage” order to the primary harvester if there is concern that the primary harvester may destroy residual fibre prior to it being harvested through a fibre recovery tenure.

- Allocate rights to use roadside and landing residual fibre to the holder of one of the following fibre recovery tenures:

- Fibre supply licence to cut

- Fibre forestry licence to cut

- Decked Timber FLTC

Learn more about Fibre Recovery Process (PDF).

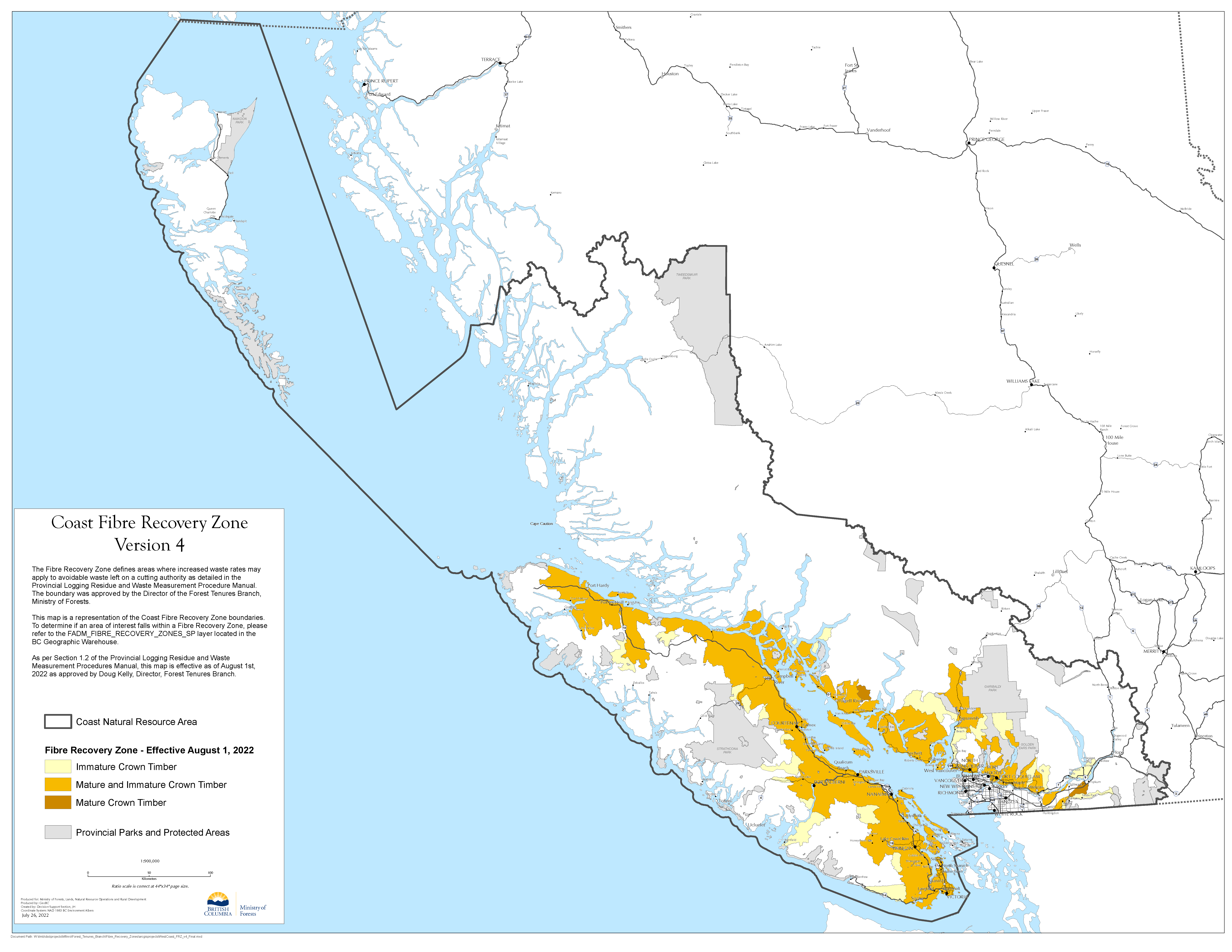

Coast Fibre Recovery Zone

The Coast Fibre Recovery Zone is one of the initiatives resulting from the Coast Forest Sector Revitalization Initiative aimed at improving harvest performance to ensure more fibre is available for domestic mills including the pulp and paper sector. It covers portions of Vancouver Island and the mainland coast where enhanced fibre recovery has been determined to be economical. Primary harvesters conducting operations within this zone will now pay triple the waste rate or $2 per cubic metre, whichever is greater, for applicable volumes of avoidable waste left on a harvest block.

- Memo Coast Fibre Recovery Zone Update - July 2022 (PDF 185KB)

- Fibre Recovery Zone Map v4 (PDF 2.6MB)

- Fibre Recovery Zone Map (iMapBC)

- To View the current zone, select the following layers under the "I want to" menu

- Add Provincial Layers

- Administrative Layers

- Fibre Recovery Zones

- Fibre Recovery Zone Version 4

- To View the current zone, select the following layers under the "I want to" menu

Alternate Methods of Scale

With Alternate Methods of Scale, new scaling policies allow logs and residual fibre to be removed from harvest sites at the same time. This will reduce costs and administrative barriers for operators to move residual fibre to market more quickly and increase the amount of material available for secondary manufacturers.

- Concurrent Residual Harvest System (CRHS)

- Simple Sampling (coast only)

- Woodchip Volume Measurement System (coast only)

Interior Grade 4 Credit

In the interior, Grade 4 Credit timber may be harvested and removed from a cutblock without having it count against their licence’s cut control position if the timber goes to a primary facility (i.e. pulp/paper, bio-energy, etc.) other than a sawmill, veneer plant, or a facility that only produces cants (time limited) and application is made to the government for a credit.

In some cases licence holders may not remove all Grade 4 timber and instead choose to pay applicable waste penalties. The Grade 4 cut control credit therefore provides a further incentive for licence holders to utilize this timber and provide opportunities to other sectors of the forest industry.

Additional information can be found on the Cut Control Administration website.

Waste Benchmarks

Some level of waste is inevitable in timber harvesting operations, and leaving some fibre, or coarse woody debris, also supports biodiversity. But in many cases, usable fibre is left in the bush only because it has a higher removal cost and limited economic value to the companies doing the harvesting. This is known as “avoidable” waste, wood waste or residual fibre.

The Province sets limits for the amount of allowable waste during timber harvesting, as well as requirements for measurement, reporting and how much companies are billed for the waste they leave behind. These limits are called waste benchmarks.

As part of Coast Forest Sector Revitalization Initiative, the Province implemented new waste benchmarks for mature stands that vary depending on the method of harvest.

Additional information can be found in the Residue and Waste Procedures Manual.

Hazard Abatement

Fire hazard assessments and hazard abatement are key activities in reducing the potential threat of wildfires arising from fuels left on the land base following industrial activities. Under the Wildfire Act a person carrying out an industrial activity or prescribed activity is required to assess and abate fire hazards as necessary. Increasing the use of residual fibre can reduce necessary activities and costs associated with fire hazard abatement.

More information on the fire hazard abatement website.

Fibre Recovery Zone Map

Important Links

Contact information

Contact us if you have questions about residual fibre recovery.

For opportunities to access residual fibre contact your natural resource district office or FrontCounterBC.