2021 Award for Workplace Health and Safety

The nominees for the 2021 Award of Excellence for Workplace Health and Safety are:

NorLand Limited

Online Training Portal

NorLand Limited’s Online Training Portal was developed to provide workers with accessible training that is focused on the activities and business practices for each employee’s work environment. The portal ensures that organizational and safety policies, programs, procedures and expectations are communicated throughout the company and ensure that employees receive timely regulatory compliance training.

To ensure a high level of comprehension, courses have been built in small modules and provide competency verification, completion certificates, real time progress and tracking, as well as reminders for staff when they are required to renew courses and certifications. To support the online learning experience, hands-on training is provided for topics that require field training, such as fall protection or work in confined spaces.

Since the training program’s inception in 2018, NorLand Limited has seen a reduction in injuries that is reflected in a 23.9% increase in their WorkSafe BC experience rating. With 1,078 personnel registered on the system and over 3,000 courses completed, NorLand continues to solicit feedback from staff regarding safety improvements, including the development of additional training material and videos. The benefits of the Online Training Portal include its flexible user and administrator platform, real time progress reporting and ability to identify knowledge gaps.

Emil Anderson Construction Ltd.

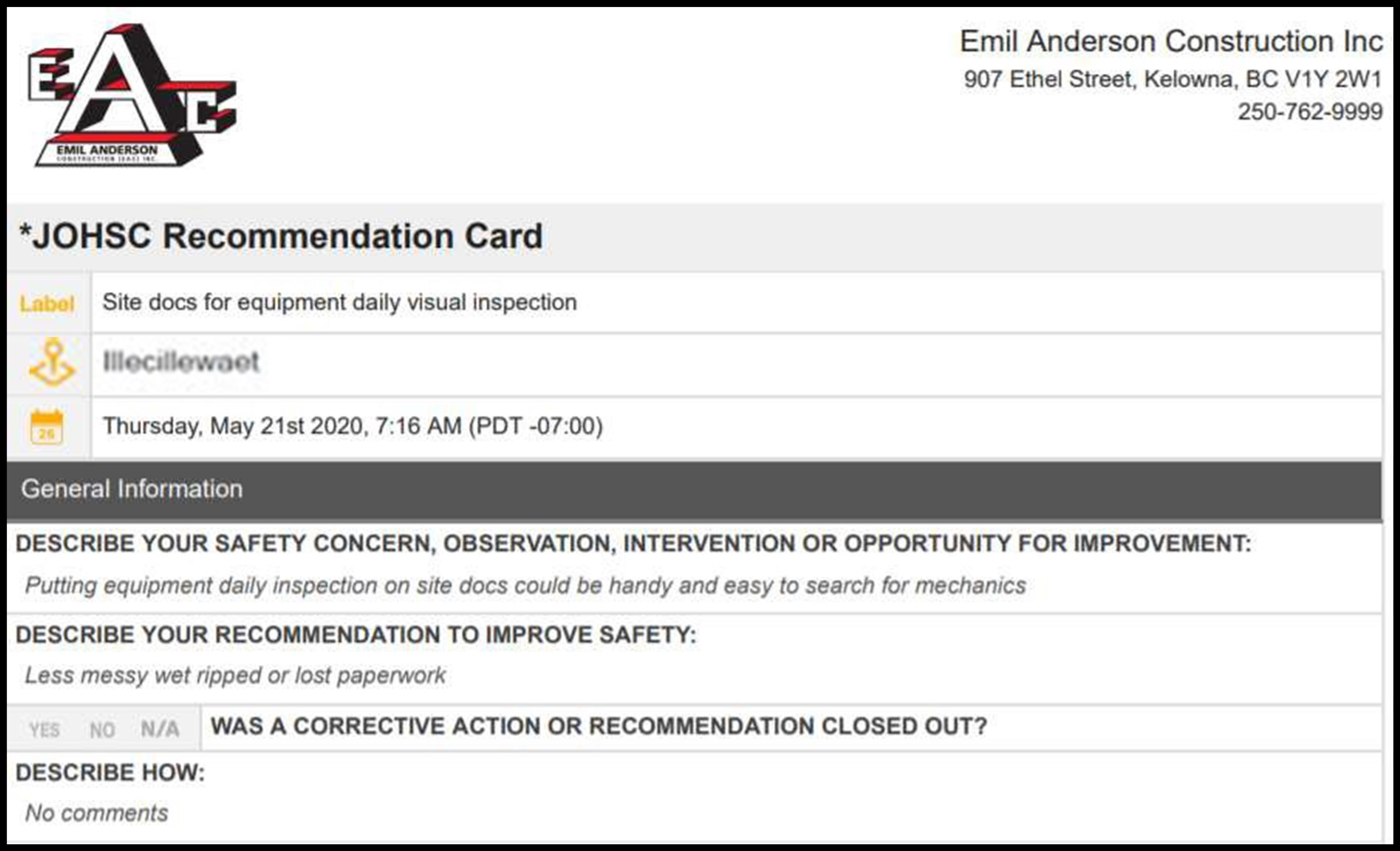

JOHSC Card Recommendation Program

The Joint Occupational Health & Safety Committee (JOHSC) Recommendation Cards were created as part of the Emil Anderson Group’s Paving the Way to Zero Initiative to provide a link between management and employees on Emil Anderson Construction (EAC) projects. Through technology and the support of the SiteDocs Paperless Safety Management System, concerns from construction workers are sent to management in live time.

Emil Anderson’s Paving the Way to Zero initiative continues to reduce workplace risk because it allows everyone to address safety concerns initiate change. Workers are coaches, mentors and trainers, and this program empowers them to improve safety and reduce risk on projects.

The JOHSC Recommendation Card Program was introduced in fall 2019 and has resulted in a Lost Time Incident Frequency of zero in the past two years. The JOHSC Recommendation Card Program gives workers a sense of accountability and ownership, allowing for continuous improvement.

Mainroad Lower Mainland Contracting Ltd.

Wearable Technology Program to Identify and Reduce Musculoskeletal Injury Risk

Mainroad Lower Mainland Contracting Ltd. partnered with LifeBooster and deployed their digital health and safety eQIP program (Electronic Quantification, Identification, and Prioritization of Risk Program) to address musculoskeletal injuries –a risk type that is costly and difficult to prevent.

The eQIP program is a wearable technology program that identifies which areas and tasks had the highest risk and prioritizes intervention strategies based on the data that was collected. The resulting risk analyses enabled the team to develop new insights to improve operational health and safety through training, process adjustment, maintenance, compliance and return-to-work processes.

The goal of this project was to reduce overall musculoskeletal injuries, build better risk mitigation programs and prevent injuries.

Yellowhead Road & Bridge (Vanderhoof) Ltd.

Underbody Blade Slide System for Snowplows

Yellowhead Road & Bridge (Vanderhoof) Ltd. introduced the Underbody Blade Slide System for Snowplows to reduces injuries to operators who change snowplow blades.

Exposure time for operators doing a blade change has been reduced by 80%, and the weight of the blades has been lessened by approximately 9-18 kilograms (20-40 pounds), causing less strain.

The potential for potential hearing loss injuries has been reduced now that operators no longer require the use of impact tools to remove or install the blades. There were zero injuries or near misses reported due to blade changes over the winter with the operators who uses the Blade Slide System.

Graham Infrastructure LP

Road to Zero Safety Initiative

The Road to Zero safety initiative was to identify key safety hazards, risks, and opportunities on the Alex Fraser Bridge while performing Pier S15 and N15 Joint Replacement Project.

The Road to Zero program establishes engineering controls to mitigate hazards. High-powered magnets were used to lift bridge plates and mechanically assist jack hammers to remove concrete. This system reduced hazards and potential injuries for workers.

NorLand Limited

Online Training Portal

Resources

Contact information

For questions about the Contractor of the Year Awards, contact us at:

778 974-6136