Biomass utilization

The ongoing effort to diversify forest biomass utilization requires the development of new technology and processes.

Next generation bio-fabric for textiles

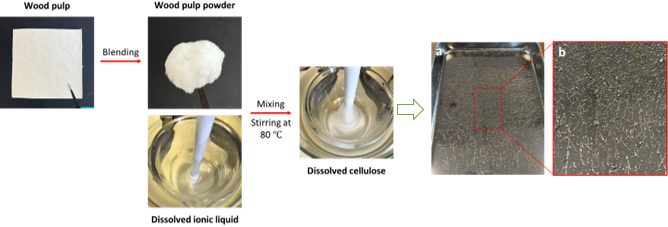

The Ministry of Forests actively supports projects at the University of British Columbia's Sustainable Functional Biomaterials Lab (SFB), led by Prof. Feng Jiang. The lab is developing technologies to convert forest biomass into fabrics. Specifically, the project aims to take northern bleached softwood kraft pulp (NBSK) and process it into nano-micro fibres, which can be further converted into next-generation bio-fabric for textile applications.

During the past year, the SFB lab at UBC has developed several technologies to produce the nano-micro fibres, including cold-alkaline swelling and mechanical disintegration, ice-templating assembly, super mass colloider grinding, and solution blow spinning. A stretchable membrane was further developed by incorporating gelatin or glycerol, to make the cellulose membrane stretchable. The SFB lab developed a hydrophobic modification strategy that can render superhydrophobicity for the cellulose membrane.

Overall, this project demonstrates the potential of utilizing NBSK as a raw material to produce textile fabric, and will support further development of fibre spinning technology for the future.