Bioeconomy and job creation

The development of the forest bioeconomy diversifies the forest industry, which creates new jobs.

On this page

- Job creation

- Advanced biomaterial jobs

- Conventional lumber, pulp, and paper jobs

- The bioproduct development pathway

Job creation

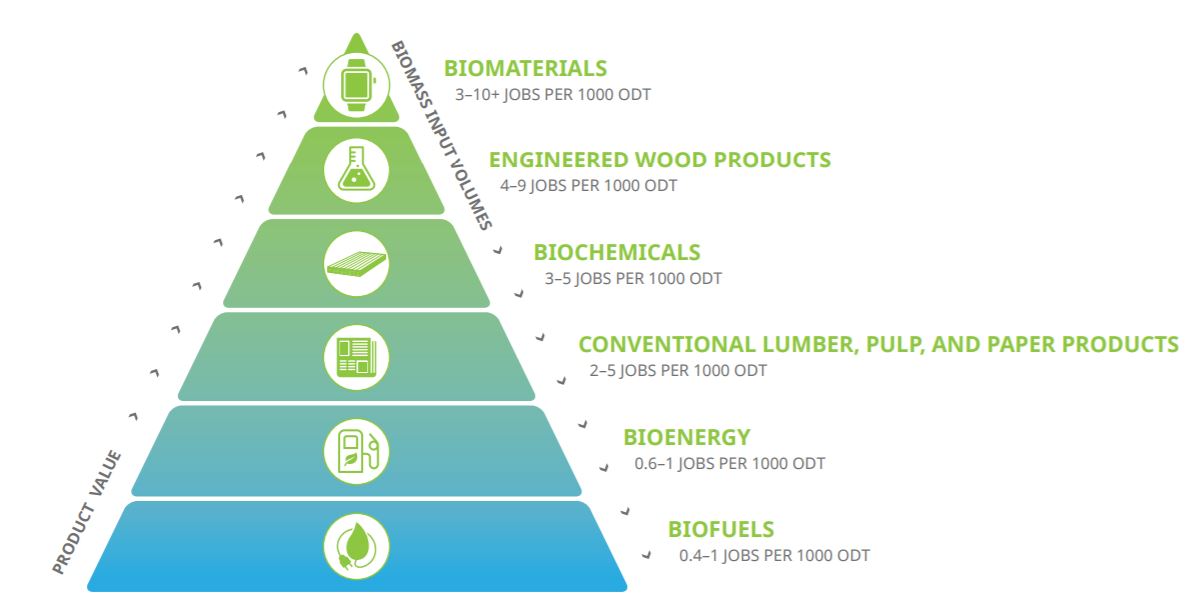

Each bioproduct within a category is projected to create a different number of jobs. Each product category then covers a range of low-end to high-end estimates depending on the specific bioproducts included.

For example, per 1000 oven-dried-tonnes (O.D.T.) of biomass feedstock, the biofuels category creates approximately 0.4 to 1 job. That is 0.4 jobs for ethanol production at the low end, and 1 job for biodiesel at the high end.

Biofuels require large amounts of biomass feedstock and involve the least value-added processing. As a result, this category creates fewer jobs per 1000 O.D.T. compared to other categories.

The bioproduct-job pyramid shows both direct and indirect employment supported through manufacturing bioproducts. This includes the entire supply chain, from tree harvesting to processing to the manufacturing of bioproducts. Job creation correlates with product value. The more processing and manufacturing required to create a bioproduct, the higher the product's market value. The estimated number of jobs are per 1000 oven-dried-tonnes (O.D.T.) of biomass feedstock.

Advanced biomaterial jobs

Advanced biomaterials require very little biomass input compared to other bioproduct categories. They also provide the most value-added steps to the manufacturing process. As a result, they are the most valuable bioproducts.

Per 1000 O.D.T biomass input, biomaterials create approximately 3 jobs when producing lower value products, such as reinforced thermoplastics, and 10 or more jobs when producing the highest value products, such as flexible transparent conductive cellulosic nanocrystals.

Examples of advanced biomaterial jobs include:

Biochemical jobs

Biochemicals are a unique product category that often use biproducts from conventional pulping processes as feedstock. These can be high-value products that require small or large amounts of biomass feedstock. Per 1000 O.D.T biomass feedstock, biochemicals create approximately three to five jobs when producing various sugars and sweeteners from hemicellulose and lignin, such as Xylitol and Vanillin.

Engineered wood product jobs

Engineered wood products (EWPs) require additional manufacturing steps, as they bind dimensional lumber, strands, particles and fibres of wood together to improve a product’s structural integrity. Some EWPs, such as cross laminated timber, involve long supply chains with multiple steps that add value to the process. Per 1000 O.D.T biomass feedstock, EWPs create approximately four jobs when producing oriented strand board, and approximately nine jobs when producing cross laminated timber.

Bioenergy jobs

Bioenergy is very similar to biofuels in its requirements for biomass feedstock and opportunities for value-added processing. Bioenergy creates approximately 0.6 jobs per 1000 O.D.T biomass feedstock to produce Renewable Natural Gas, and 1 job to produce wood pellets.

Conventional lumber, pulp and paper jobs

Conventional lumber, pulp, and paper products require relatively large amounts of biomass feedstock, but they provide more opportunities for value-added processing. This category creates approximately two jobs per 1000 O.D.T for pulp products, and five jobs per 1000 O.D.T for high quality paper packaging products.

The bioproduct development pathway

All categories offer opportunities for bioproduct development. However, the bioproduct development pathway is important to consider. Saw logs are best used in conventional lumber and engineered wood products. Residuals from saw milling and harvesting, as well as material that is non-sawlog grade can be used in pulp and paper products. Then the residuals from biomaterial, biochemical, and pulp and paper manufacturing can be used in the production of bioenergy and biofuel. This type of pathway ensures an approach that maximizes the economic, social and environmental value from B.C.’s forest biomass.