Actions and success stories in plastic reduction

Government is committed to phasing out single-use plastics and transitioning to the circular economy.

On this page, learn more about some of the actions we're taking to fulfil these commitments.

On this page

Circular economy

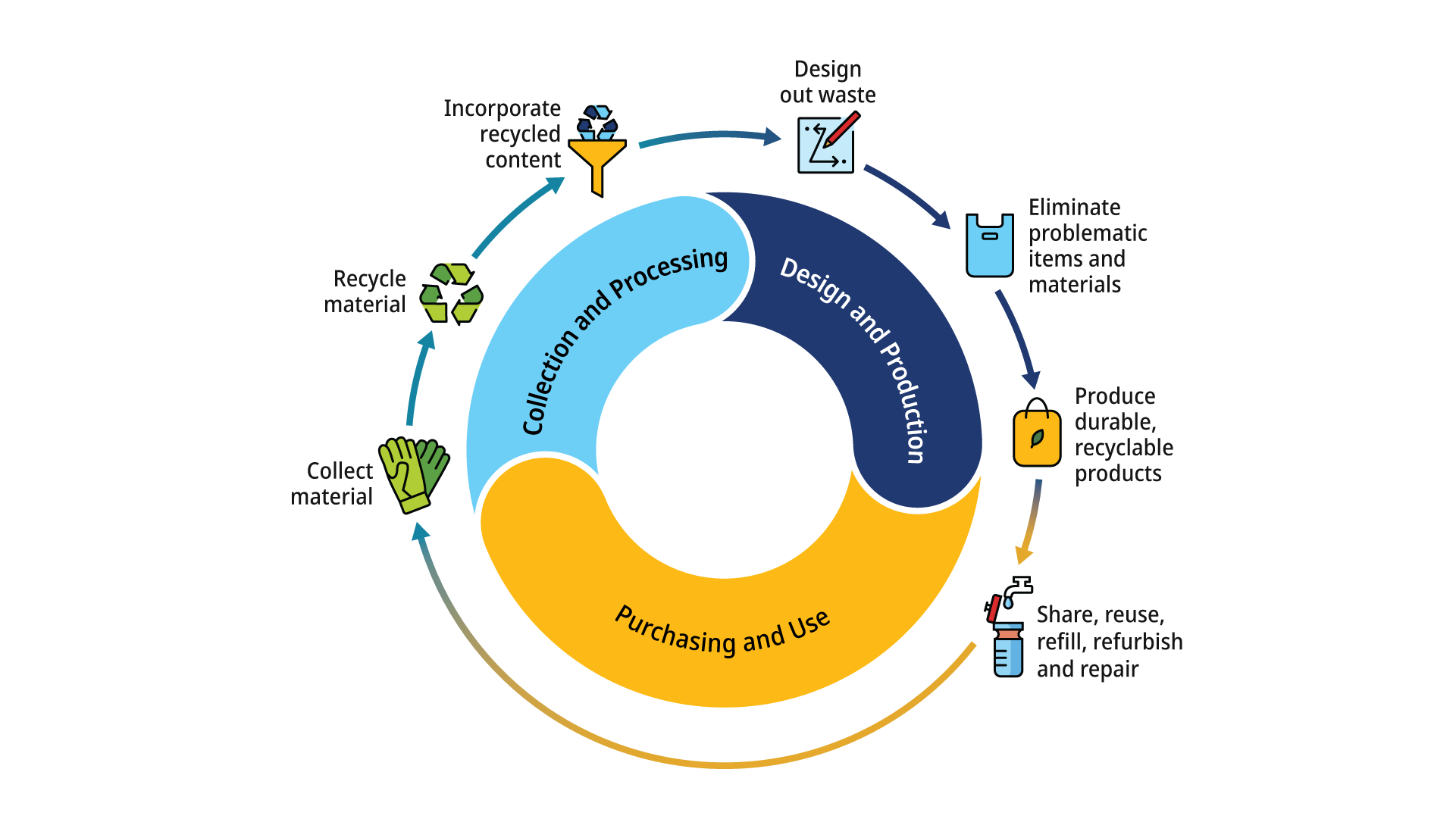

In a circular economy, resources are never tossed but instead are reused, recycled and reintroduced as new products.

Actions to reduce plastic waste

Here are some examples of the actions we're taking in B.C. to reduce single-use plastics and move toward a circular economy.

B.C.'s recycling system

In B.C., producers of products listed under the Recycling Regulation are responsible for the life cycle of the products they make, including:

- Collecting product waste

- For example: residential household collection or recycling depots

- The end-of-life waste management of that product

- Such as, reuse and recycling

This waste management approach is called Extended Producer Responsibility (EPR).

To learn more about B.C.’s EPR programs, visit Recycling.

Non-residential packaging waste

While over 99% of British Columbians have access to recycling at home through curbside blue boxes, multi-family building recycling programs or depot services, recycling and waste prevention outside of the home at locations such as offices, retail stores, restaurants, warehouses, manufacturing facilities, institutions and schools is not as consistent.

Find out more about engagement on Non-residential (Industrial, Commercial and Institutional – ICI) waste here.

Investments in plastic waste solutions

B.C. has invested nearly $40 million in plastic waste prevention through the CleanBC Plastics Action Fund.

Learn more about the CleanBC Plastics Action Fund.

Investments in shoreline cleanups

Through the Clean Coast, Clean Waters Initiative Fund, B.C. has provided nearly $50 million in funding to First Nations, local communities and businesses to remove debris and derelict vessels from B.C.’s coastline.

Learn more about the Clean Coast, Clean Waters Initiative Fund.

Success stories

Fresh Prep Zero Waste Kit

With funding from the CleanBC Plastics Action Fund, Fresh Prep – a meal-prep delivery service – were able to increase the use of their Fresh Prep Zero Waste Kit, preventing over 100 tonnes of plastics annually. A first for the industry, the kit allows customers to enjoy the same level of convenience with no plastic waste.

Ocean Legacy Foundation Legacy PlasticTM

At their marine debris recycling facility in Steveston, BC, Ocean Legacy Foundation (OLF) has been turning plastics recovered during ocean, shoreline and marine equipment clean-ups into plastic pellets called Legacy PlasticTM. Legacy PlasticTM is the first commercially available plastic pellet in North America made from ocean and shoreline recovered plastic. The CleanBC Plastics Action Fund increased OLF’s processing capacity and their recycling facility has been key to Clean Coast Clean Waters achieving a 65% recycling / upcycling rate for shoreline clean-up projects.

Contact information

Know of a plastic reduction success story? Share it with us!

Plastics@gov.bc.ca