Livestock and poultry - 9.4 Egg handling

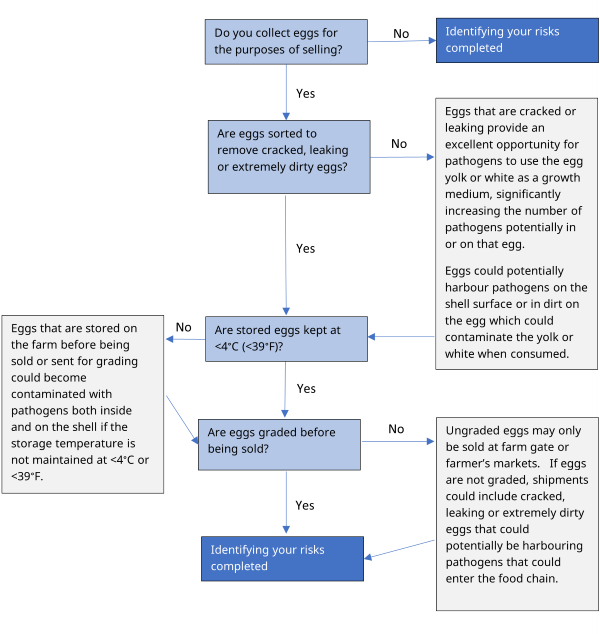

If eggs are not produced, collected and stored properly, contamination of the egg can occur.

This good agricultural practice applies to all egg farms, including those that do not hold quota. Farms that hold quota are also required to follow the British Columbia Egg Marketing Board requirements that are not included here.

What needs to be done

Manage the flock and collect and store eggs properly to reduce contamination from occurring.

How to do it

Collection:

- Collect eggs at a minimum frequency of daily, and more frequently in warmer or extreme weather. As most hens lay the majority of eggs in the morning, it is best to collect them as soon as possible after they are laid to reduce the opportunity for bacterial growth

- Collect eggs in clean trays, baskets or containers. If trays are made of cardboard and cannot be cleaned, they should be used only once and then discarded. If they are made of metal wire and plastic coating, and are reused, make sure to wash and clean them properly with appropriate sanitizers

- Handle eggs carefully to prevent cracking

- Remove all eggs that are cracked, leaking or extremely dirty (fecally contaminated) as they are likely to be contaminated with bacteria. Dispose of them appropriately

Cleaning and grading

- Do not cool eggs rapidly before they are cleaned, as the shell will contract and pull any dirt or bacteria on the surface into the pores of the egg

- Clean the eggs as soon as you collect them. This eliminates sources of contamination and loss of interior quality. Wash eggs with potable water 10 degrees warmer than the egg. This will make the egg contents swell and push the dirt away from the pores of the egg. If the eggs are extremely dirty a mild detergent approved for egg washing can be used. Never let eggs sit in water, as once the temperature equalizes, the egg can absorb contaminants from the water

- Dry and cool eggs quickly after washing, store in a refrigerator at less than 4°C

- Know the Egg Grading and Standards Regulation

Storage:

- Sort uncracked, undamaged eggs on clean surfaces, and store them in clean containers

- Store eggs in a refrigerator (under 4°C and 70 to75 percent relative humidity) as soon as possible after collecting and cleaning

- Store cleaned eggs with the small end down to keep the air cell stable during storage

- Label cartons with the farm name and address so you can identify your eggs

- Date the tray/carton so you can use or sell the oldest eggs first. Try to use or sell all eggs before they are three weeks old

- Never store eggs with odorous (smelly) materials, as eggs absorb odours from other foods (for example fish, onions) or from chemicals

- Never leave eggs at room temperatures as warm, dry environments will cause decreased interior quality and increases food safety risks

- Store empty egg trays off the floor

Coop management:

- Keep the flock in a fenced area so they cannot hide their eggs from daily collection

- Keep the environment clean and dry which will keep the eggs clean. A muddy run, or damp and dirty nesting material will result in dirty, stained eggs

- Maintain a pest control program to keep pests away from the hen house. Pests carry Salmonella and can contaminate the nesting boxes and eggs

Records to keep

It is a best management practice to keep records regarding your food safety practices should a food safety concern arise on your farm. These records may include a daily temperature monitoring record of the storage area, (or your own record) that includes:

- Annual flock environment lab-tests for Salmonella Enteritis (SE)

- Date/time

- Initials

- Pest control program records

- Temperature

- Water quality lab-test results for on-site water systems

Laws and regulations

- The Egg Grading and Standards Regulation, under the Food and Agricultural Products Classification Act, prohibits the distribution within B.C. of eggs that are not graded, processed and marked in accordance with the Safe Food for Canadians Regulation, with a few exceptions

- The Egg Grading and Standards Regulation does not apply to eggs that are produced on the producer’s own farm and are distributed directly to consumers at the producer’s farm or residence

Forms

| Go back to 9.3 Milking practices | Proceed to 10.1 Training |